Laser etching uses pulsed fibre laser at high frequencies to remove predefined materials on the mold based on an entirely digital process of texture mapping in software and automated execution by laser machine.

The toolmaker simply provide the 3D mold file, choose a texture and its depth, and our engineers will program the information using 3D software. Executing the prepared program, the laser machine will remove the material on the mold layer by layer to result in a texture.

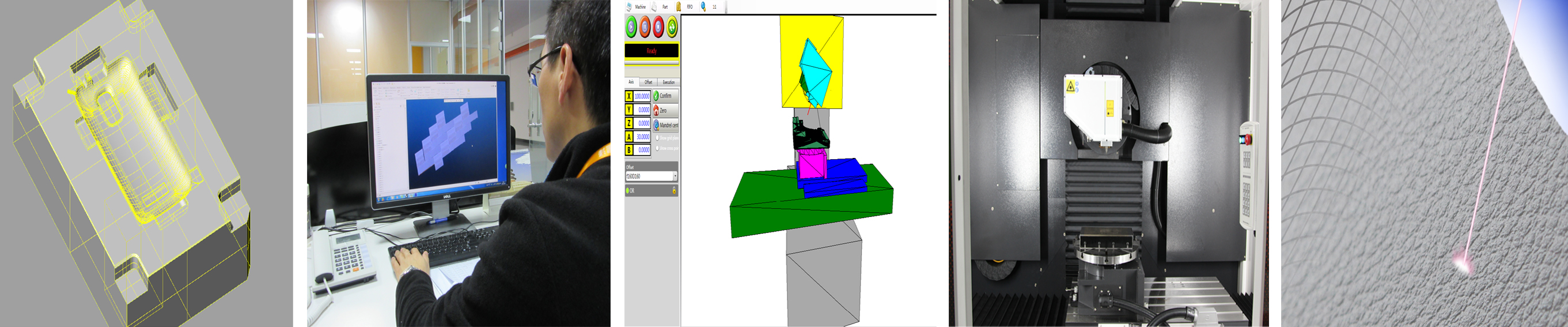

The laser texturing process

1. Client provides 3D mold file and confirm texture

2. Engineer uses 3D software to program

3. simulation of laser application before actual application

4. pinpoint mold location on machine

5. Start laser application of texture on to the mold

After laser etching of the desired texture, the texture can further be polished by our laser machine to achieve a specific level of polish. the mold can then be further treated by external polishing, chrome or other metals plating, and more. Please contact us for details and browse About Us, Purchase Plaques, Knowledge.

Home